|

SKY WIN Technology Co., Ltd.

|

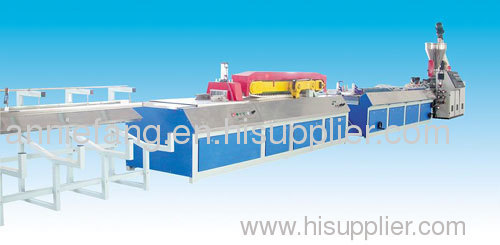

PVC Wood Foamed Flooring Extrusion Line PVC Wood Conical Twin-screw Machines

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Practical Application: To extrude WPC indoor flooring directly, and then hot-stamp, or print it on the surface

- Detailed Product Description: PVC Wood Foamed Flooring Extrusion Line

WPC(PVC foam+wood) Indoor Flooring Lines:

I. Practical Application: To extrude WPC indoor flooring directly, and then hot-stamp, or print it on the surface (with other downstream machines for additional processing).

II. Advantages of WPC indoor flooring:

1. To use foamed PVC+ wood technology to be light (density 0.9-1).

2. Waterproof.

3. Environmental friendly, without formaldehyde emitted.

4. No crack, small deformation.

III. Extrusion Machines and upstream & downstream machines:

I. Practical Application: To extrude WPC indoor flooring directly, and then hot-stamp, or print it on the surface (with other downstream machines for additional processing).

II. Advantages of WPC indoor flooring:

1. To use foamed PVC+ wood technology to be light (density 0.9-1).

2. Waterproof.

3. Environmental friendly, without formaldehyde emitted.

4. No crack, small deformation.

III. Extrusion Machines and upstream & downstream machines:

| Name | Output (Kg/hr) | Power (KW/set) | Quantity (set/unit) | |

| SWMSX-3 | PVC+ wood flooring extrusion line | 80-130 | 72 | 1 |

| SWHL200/500 | Mixing unit | 200 | 66 | 1 |

| SWPS400 | Crusher | 400 | 15 | 1 |

| Double-end cutting machine | 6.25 | 1 | ||

| Flooring mold | 1 | |||

| Hot-stamping or printing machine for WPC flooring (with UV painting) | 1 | |||

| Other upstream machines such as power |

Related Search

Wood Plastic Extrusion Line

Conical Twin Screw Extruder

Twin Conical Screw Barrel

Conical Twin Screw Barrels

Pvc Wood

Wood Pvc

More>>